Your partner in subcontracting

Gilbos NV has been an active supplier to the subcontracting market for more than 30 years. You can find some of our long term partners below.

- ERP driven production

- From raw material to finished part we can offer you a turn key solution

- High quality craftsmanship is our standard

- Environmental and Socially conscious in our manufacturing processes

- Clear and concise communication

- We offer a wide range of surface treatments to meet your needs

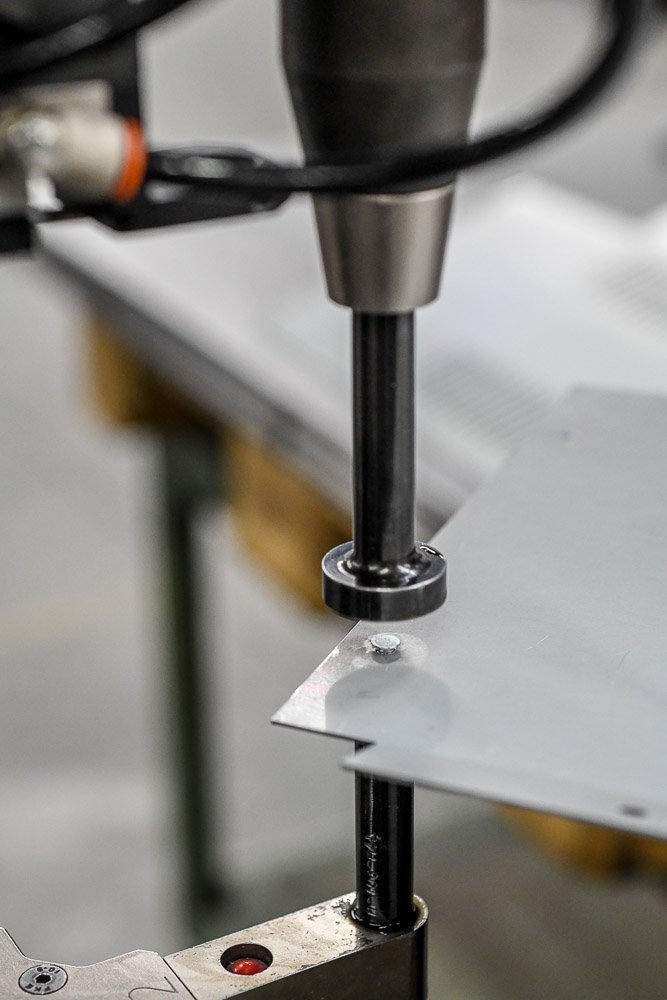

Sheetmetal

Our experienced craftsman are focused on providing high quality products and complete customer satisfaction.

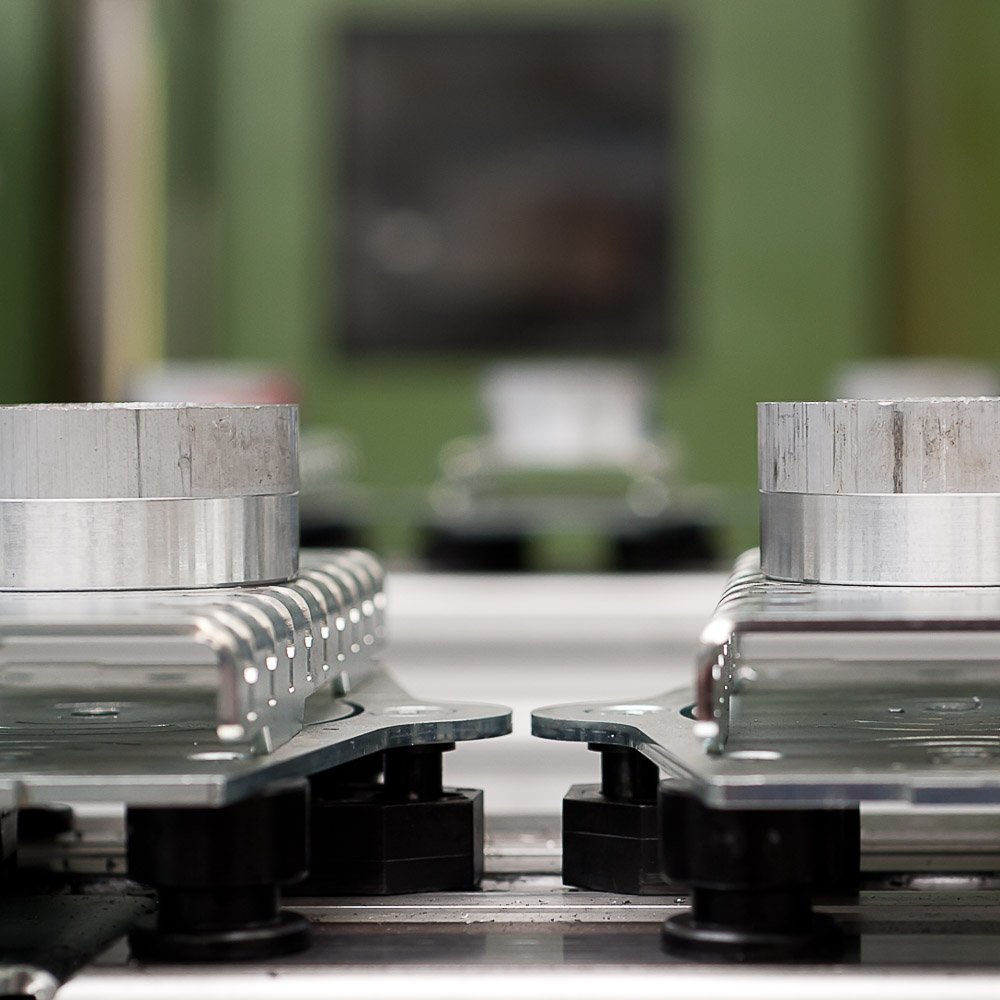

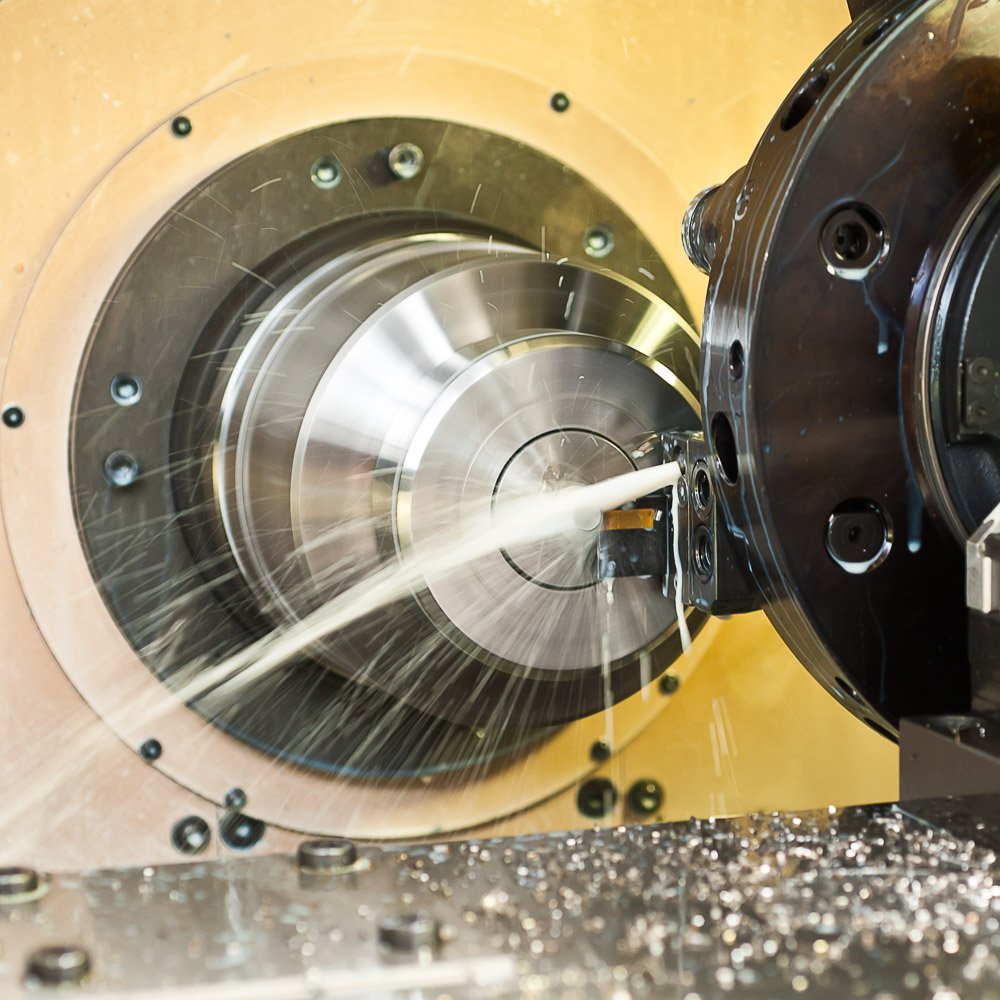

Machining

Gilbos NV is continually automating it’s processes to remain competitive in the subcontracting market.

Surface treatments

From stainless steel to plastic substrates, we can provide the materials you require.

Powder coating and conventional liquid paint, thats our core business in surface treatment. Online or offline are posibility’s

Online: 2200 mm x 1300 mm x 900 mm, Offline: 4000 mm x 2000 mm x 2000 mm.

Most of the RAL colours are available or deliverable on short notice.

You want a custom made supplier from your paint supplier, no problem for us.

Furthermore we have a wide range of suppliers that can perform most of the surface treatments, zinc plating, anodising, …

Powder coating

Part preparation processes – Chemical pre-treatments involve the use of phosphates.

Online

Online and semi automatisation with powder recuperation

Conventional liquid paint

Off line painting is more time consuming and mostly used for plastic parts and sizes that do not fit the online dimensions.

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are fabricated from sheet metal. Thicknesses can vary significantly.

We can perform the complete process in our workshop, from lasercutting, inserting, welding, …

Laser cutting

Trumpf Fiber Laser 3030 with Liftmaster Trustore 3030

X-as = 3000 mm

Y-as = 1500 mm

Max lasercapacity = 3000W

Max plate size steel = 20 mm

Max plate size stainless steel = 15 mm

Max plate size Alu = 15 mm

Max plate size copper = 6 mm

Max plate size brass = 6 mm

Bending

LVD – Trumpf Trubend

1350 KN – 4000 mm

1000 KN – 3000 mm

500 KN – 2500 mm

Welding

Mig/Mag

Tig

Spot welding

The three principal machining processes can be performed in our workshop. Turning, drilling and milling, other as shaping, planing, boring, broaching and sawing are offcourse involved.

Contact

Automated turning

DMG CTX310: dia 51 mm, Z= 450 mm

DMG CTX510: dia 160 mm, Z= 1050 mm

Emco Hyperturn 45: dia 45 mm, Z= 1200 mm

Emco Hyperturn 665: dia 250 mm, Z= 610 mm

Emco Maxxturn 65: dia 65 mm, Z= 500 mm

Milling

Unisign Univers:

X=3000 mm, Y= 450 mm, Z= 400 mm

DMG DMU50:

X= 500 mm, Y= 450 mm, Z= 400 mm

DMG 1030:

X= 1050 mm, Y= 500 mm, Z= 400 mm

Heller MC:

X=800 mm, Y= 800 mmm, Z= 800 mm

Offline turning

Mainly for smaller lot sizes:

Dia 250 mm, Z = 1200 mm